For ships out in rough seas, the failure of machinery on deck means an end to the journey or considerably slowed maneuvers, including the associated high financial costs. For this reason, some components are often replaced every time the machine is serviced. The new incremental rotary encoder POG 83 withstands all adverse conditions on deck without failures, offering a service life of several maintenance intervals for winches and cranes.

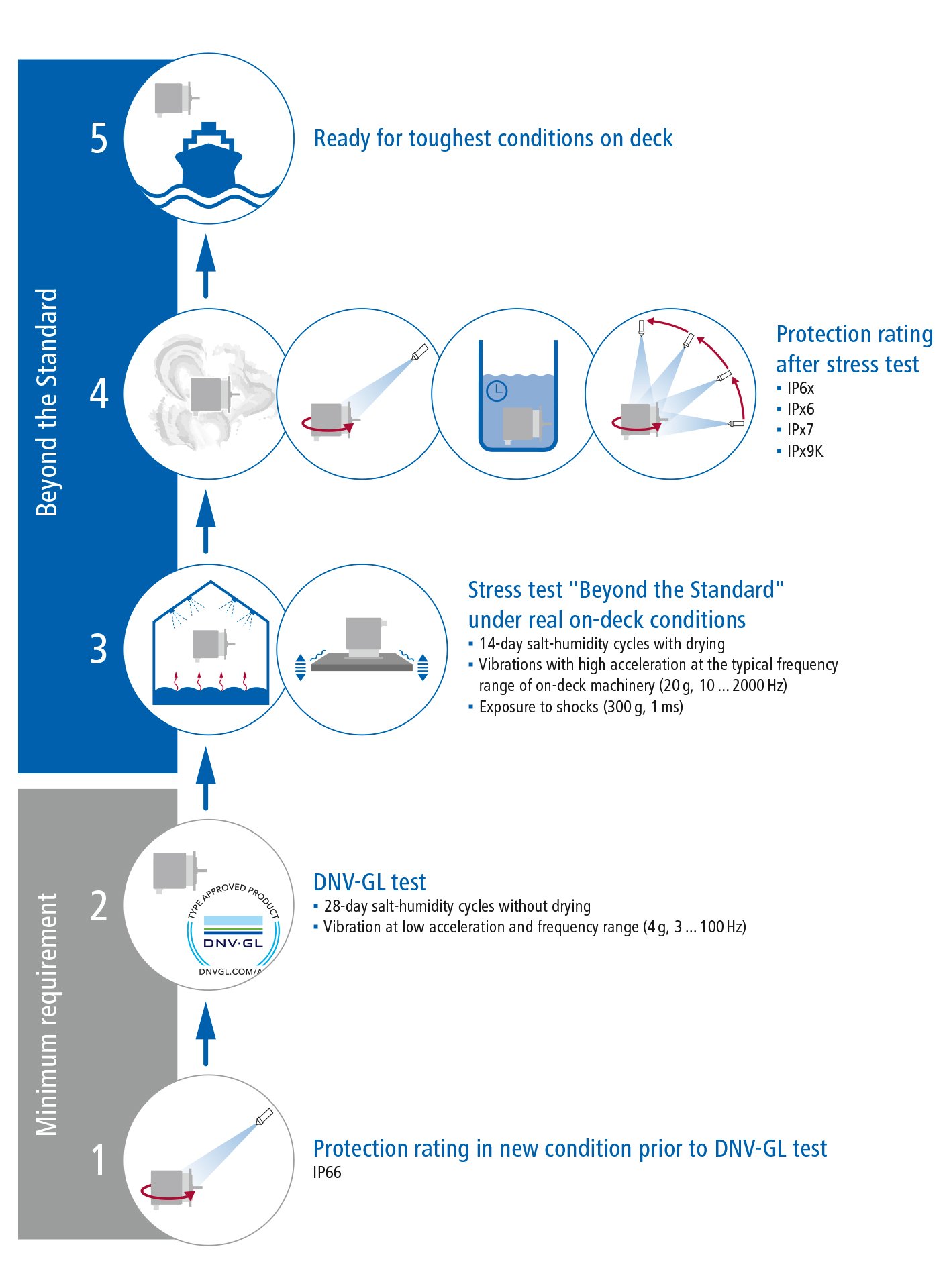

The HeavyDuty expertise of Baumer is incorporated into the design and tightness, which are unparalleled in the sector. The long-term tight design of the POG 83 as well as the robust stainless steel design protect it from the penetration of water, humidity, and corrosion. Intensive stress tests simulate typical mechanical loads caused by waves and docking maneuvers as well as the occurrence of extreme weather with alternating salt water flooding and drying. The POG83 is cyclically exposed several times to the respective conditions. Only then are the functional and protective category tests performed – the encoder durably complies with IP66, IP67, and IP69K. These verifications along with the experience in applications on deck provide reliability for many years of service in maritime applications, such as loading and unloading, hauling in nets, or anchoring. A version with DNV-GL facilitates the ship and system approval process for users. The rotary encoder has a drive shaft diameter of 11 millimeters, can be installed via EURO flange B10, and features an M23 connection made of stainless steel.