By 2025, we can expect ifm electronic devices to showcase some amazing advancements in sensor integration, making it easier than ever to collect real-time data and make informed decisions. These sensors are set to become more interconnected, tapping into the power of the Internet of Things (IoT) to deliver insights that help businesses run more efficiently. On top of that, breakthroughs in artificial intelligence and machine learning will pave the way for predictive maintenance, which means companies can anticipate and fix issues before they lead to costly downtime.

As more industries embrace these cutting-edge innovations, the demand for reliable and adaptable ifm sensors will grow, pushing the evolution of automation technology forward. This transformation is set to change the way manufacturing processes are handled across various sectors, making them smarter and more efficient than ever before.

Industrial Overview

Sensor Integration and Real-Time Data:

Companies like ifm electronic are indeed focusing on integrating sensors with advanced data collection capabilities. The trend toward real-time data monitoring is supported by the growth of IoT technologies, which allow devices to connect and share information seamlessly.

Sensor Integration and Real-Time Data:

Companies like ifm electronic are indeed focusing on integrating sensors with advanced data collection capabilities. The trend toward real-time data monitoring is supported by the growth of IoT technologies, which allow devices to connect and share information seamlessly.

Interconnected Sensors and IoT:

The Internet of Things (IoT) is a major trend in industrial automation, enabling devices to communicate with each other. Ifm electronic has been developing sensors that leverage IoT for improved data analytics and operational efficiency.

Artificial Intelligence and Machine Learning:

The integration of AI and machine learning into industrial processes is a growing trend. Predictive maintenance powered by these technologies allows companies to forecast equipment failures and schedule maintenance proactively, reducing downtime and costs.

Demand for Reliable and Adaptable Sensors:

As industries increasingly adopt automation and IoT technologies, the demand for reliable sensors is indeed on the rise. Ifm electronic is well-positioned in the market due to its reputation for producing high-quality, adaptable sensor solutions.

Transformation of Manufacturing Processes:

The shift toward smarter manufacturing processes is a recognized trend in the industry. Automation technologies, including advanced sensors, are transforming operational workflows across various sectors, leading to enhanced efficiency and productivity.

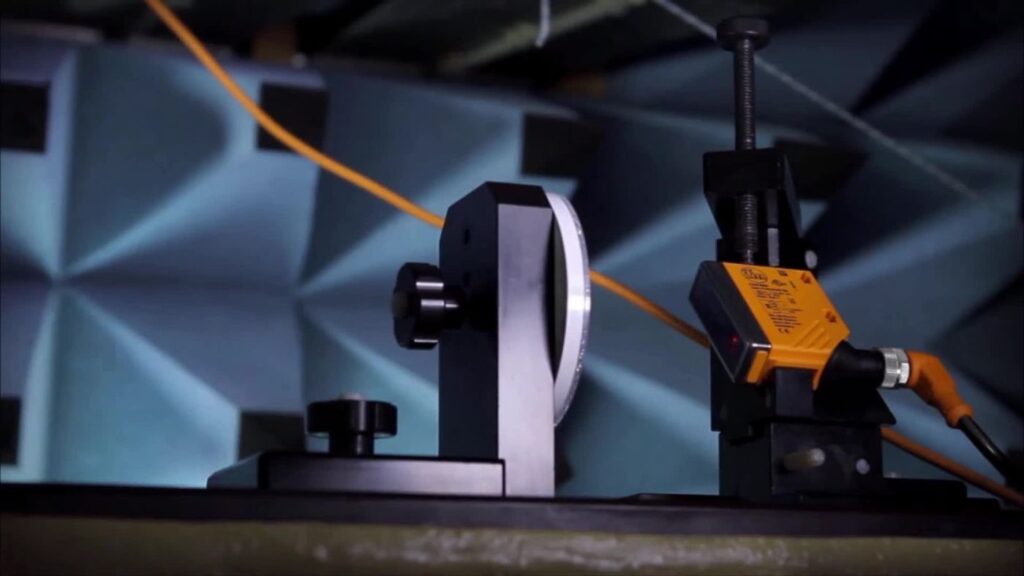

Overview of IFM Sensors

ifm electronic sensors are transforming industrial automation by utilizing advanced technology for enhanced integration and data flow.

By leveraging the Internet of Things (IoT), these sensors provide real-time monitoring and analytics, enabling quick decision-making. Their connectivity improves operational efficiency, while the use of artificial intelligence and machine learning allows for predictive maintenance, reducing downtime. Overall, ifm sensors are reshaping automation technology.

Future Trends in Sensor Integration

As we move deeper into the realm of industrial automation, future trends in sensor integration are rapidly evolving.

ifm electronic devices are at the forefront, harnessing advanced connectivity to enhance operational efficiency. The integration of artificial intelligence and machine learning with these sensors will revolutionize data analytics, enabling businesses to predict maintenance needs and optimize processes.

Moreover, the rise of IoT is fostering a more interconnected ecosystem, allowing sensors to communicate seamlessly. This interconnectedness not only streamlines data collection but also empowers companies to make informed decisions swiftly, paving the way for smarter manufacturing practices across industries.

IFM Sensors with IoT and AI technologies is expected to rise significantly by 2025

By 2025, the integration of IoT and AI technologies into ifm sensors is projected to surge significantly. This evolution will enable these devices to collect and analyze vast amounts of real-time data, facilitating smarter decision-making processes. With enhanced connectivity, IFM electronic sensors will seamlessly communicate within networks, driving unprecedented operational efficiency.

Furthermore, the incorporation of AI will allow for advanced predictive maintenance capabilities, helping companies anticipate equipment failures before they occur. As industrial automation continues to evolve, ifm sensors will play a pivotal role in transforming manufacturing practices, making them more responsive and adaptive to changing demands.

Innovations in IFM Electronic Devices

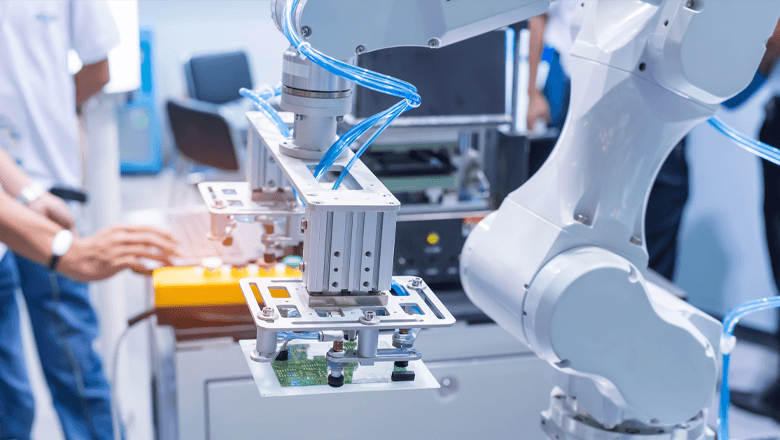

IFM Electronic devices are at the forefront of innovations in industrial automation, showcasing remarkable advancements in sensor technology.

By integrating cutting-edge features such as enhanced communication protocols, these devices improve data accuracy and speed. The latest innovations include smart sensors capable of self-diagnosis, allowing for timely maintenance and reducing operational disruptions.

Additionally, ifm is leveraging artificial intelligence to facilitate advanced analytics, which empowers businesses to make predictive decisions based on real-time data. As industries increasingly adopt these sophisticated solutions, ifm electronic devices are set to redefine efficiency and reliability across manufacturing processes, heralding a new era in automation.

Impact on Industrial Automation

Ifm sensors are important for enhancing industrial automation by delivering accurate data that improves operational efficiency. They enable effective machine communication within networked systems and incorporate advanced features such as real-time monitoring and predictive maintenance. This reduces downtime and optimizes resources.

Additionally, the integration of artificial intelligence and the Internet of Things with ifm sensors allows businesses to analyze data trends quickly, facilitating informed decision-making and transforming manufacturing processes across different sectors.

Ifm electronic sensors are revolutionizing industrial automation by providing accurate data that enhances operational efficiency. These sensors enable seamless machine communication within networked systems and feature real-time monitoring and predictive maintenance capabilities, which minimize downtime and optimize resources.

The integration of artificial intelligence and IoT allows for quick data trend analysis, facilitating informed decision-making and transforming manufacturing processes across various sectors, leading to significant benefits such as increased efficiency and reduced downtime.

Challenges and Considerations

Adopting new ifm sensor technologies in industrial automation presents several challenges that organizations must navigate.

First, the integration of advanced sensors into existing systems can be complex, often requiring significant adjustments to workflows and staff training. Companies may also face resistance to change from employees who are accustomed to traditional methods.

Additionally, the cost of upgrading infrastructure to support these innovative sensors can be a barrier, especially for smaller businesses. Data security concerns also arise, as increased connectivity through the Internet of Things (IoT) demands robust cybersecurity measures to protect sensitive information. Addressing these challenges is crucial for successful implementation.

Integrating ifm electronic devices into existing industrial automation systems poses significant challenges that businesses must address. One major concern is the cost associated with upgrading infrastructure to support advanced sensor technologies, which can strain budgets, especially for smaller enterprises.

Additionally, workforce training becomes essential, as employees need to adapt to new systems and workflows, potentially facing resistance to change.

Furthermore, organizations must consider the complexities of technology adaptation, as seamless integration requires careful planning and execution. Overall, navigating these challenges is crucial for maximizing the benefits of ifm’s innovative sensors in industrial automation.

In conclusion, the future of ifm sensors in 2025 promises to be a pivotal component of industrial automation. As innovations continue to emerge and integration with advanced technologies becomes more prevalent, ifm electronic devices will play a crucial role in shaping efficient and intelligent manufacturing environments. Staying informed about these trends will be essential for businesses aiming to remain competitive in the evolving landscape.