Safety is paramount in any industrial environment. Pilz safety relays play a crucial role in protecting personnel and equipment by reliably monitoring safety functions and triggering appropriate actions when hazards are detected. This guide provides a simplified overview of Pilz safety relays, explaining their function, benefits, and common applications.

What are Pilz Safety Relays?

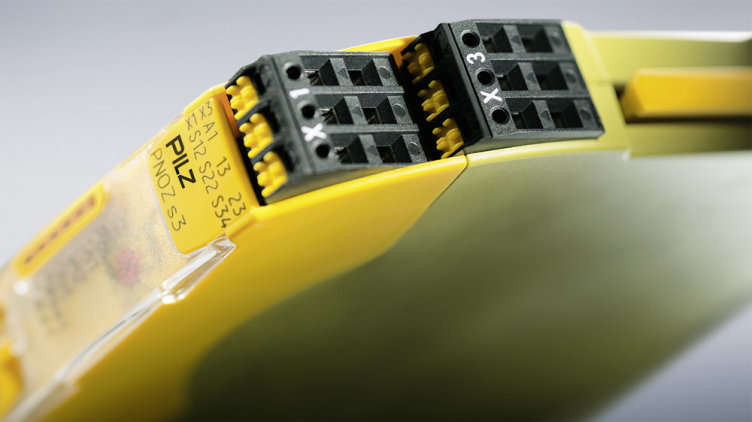

Pilz is a leading global automation technology company specializing in safety. Their safety relays are electronic devices designed to monitor safety-related inputs, such as emergency stop buttons, safety gates, and light curtains. When a hazardous situation is detected, the relay quickly and reliably switches off the controlled equipment, preventing accidents and minimizing damage. Unlike standard relays, safety relays incorporate redundant circuits and self-monitoring capabilities to ensure a high level of reliability and safety.

How do Pilz Safety Relays Work?

Pilz safety relays monitor safety circuits for interruptions or changes. For example, if an emergency stop button is pressed, the circuit is broken, and the safety relay detects this change. The relay then immediately isolates the power supply to the hazardous machine, bringing it to a safe stop. The relay remains in this safe state until manually reset, ensuring the hazard is cleared before operation resumes. This forced-guided contact principle ensures the relay’s contacts open even if internal components fail.

Key Benefits of using Pilz Safety Relays

Pilz safety relays offer several significant advantages

Enhanced Safety

They provide a reliable and robust solution for safeguarding personnel and equipment in hazardous environments.

Reduced Risk

Their advanced self-monitoring capabilities help minimize the risk of dangerous failures.

Increased Productivity

By reliably preventing accidents and downtime, they contribute to improved overall productivity.

Simplified Wiring

Pre-wired relay modules and clear terminal markings simplify installation and reduce wiring errors.

Cost-Effective

While prioritizing safety, Pilz relays also offer a cost-effective solution for many applications compared to more complex safety systems.

International Standards Compliance

Pilz relays meet and often exceed international safety standards (e.g., IEC 61508, ISO 13849-1), providing assurance of their reliability and effectiveness.

Common Applications of Pilz Safety Relays

Pilz safety relays are used in a diverse range of industrial applications, including

Emergency Stop Circuits

Monitoring emergency stop buttons and triggering immediate shutdown.

Safety Gate Monitoring

Ensuring machines cannot operate while safety gates are open.

Two-Hand Control Systems

Requiring both hands to be engaged on control buttons to prevent accidental operation.

Light Curtain Protection

Monitoring light curtains to detect intrusions into hazardous areas and stopping machine operation.

Press Brake Safety

Protecting operators from crushing hazards in press brake applications.

Choosing the Right Pilz Safety Relay

Selecting the appropriate safety relay depends on the specific application requirements.

Factors to consider include the number of safety inputs and outputs, the type of monitored safety function, and the required safety level. Pilz offers a wide range of safety relays with varying functionalities, allowing for tailored solutions to meet diverse needs. Consulting with a safety expert or referring to Pilz’s comprehensive documentation is highly recommended to ensure the chosen relay meets the necessary safety requirements.

Pilz safety relays are essential components for ensuring machine safety in industrial environments. By understanding their function, benefits, and applications, you can effectively implement these devices to protect personnel and equipment while optimizing productivity. Remember always to consult the specific product documentation and relevant safety standards for your particular application.